Home / Pirelli Tire Workshop Sealed Curing Floor Project

Recent post

contact us

Contact Person

The ground in the tire workshop can also shine? Let's take a look at the effect of the ground in the Pirelli tire shop! Pirelli (China) Tire Co., Ltd. is a joint venture between Huaqin Group and the world's top 500 Italian Pirelli Group. It has an annual production capacity of 1.2 million sets of all-steel radial tires and 10 million sets of top-class car tires. It has become an emerging Asia. Top tire development and manufacturing center. Regarding the choice of the tire shop floor, the Pirelli Group also has its own considerations.

The Pirelli tire workshop started with a diamond-resistant floor. The shelf life of the wear-resistant floor is slightly longer than other floors, but it also has many limitations. The wear-resistant floor will cause dusting and sanding problems, and the wear-resistant floor will be resistant to oil and water, and maintenance will be troublesome. Moreover, the wear-resistant floor warranty period is 1-3 years. If the use is not good, the ground life of the workshop will be shorter, and it will take a long time to renovate the old ground.

The Pirelli Group is a customer introduced by the local director Li of Shandong Jining. Through his referral, we met the person in charge of the Pirelli Group; after many visits and barrier-free communication, this rigorous person in charge was finally moved by our sincerity and gave us an opportunity to renovate the old ground. We first gave them a few hundred square meters of old ground renovation. The owners were very satisfied with the renovation effect of the old ground floor of the tire workshop, and handed the groundwork of the tire workshop to our hands!

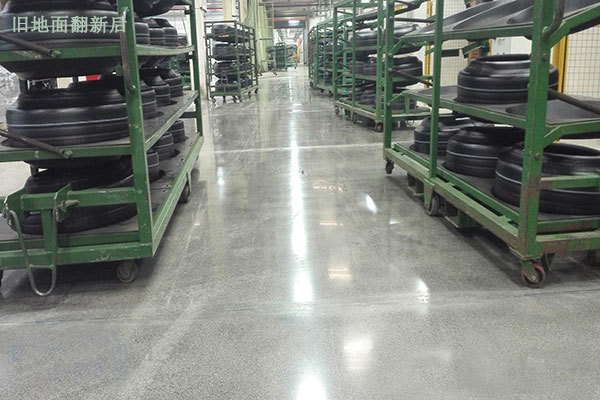

Tianjin Kaida Science And Technology Co., Ltd. has successively undertaken many old ground renovation projects on the ground of Pirelli tire workshop and floor seal curing floor project of tire workshop, which has been highly praised by Pirelli owners. With the recognition of Pirelli, we have obtained More opportunities have been officially launched for long-term cooperation with the Pirelli Group. Pirelli's new tire workshop uses wear-resistant + seal-cured floor. KAIDA concrete seal curing agent is selected to produce chemical reaction with high-quality C30 Portland cement. The concrete is penetrated 5-8mm to effectively block the pores on the concrete floor and form it. A solid, solid whole. The addition of Emery wear-resistant aggregates makes the ground more durable! When the tire workshop floor is officially put into use, you can find that the wear resistance coefficient will increase, and the Mohs hardness will be at least 8 or more, equivalent to the "King of Jade" jade!

Through several years of use, KAIDA seal curing floor is more recognized, and the strength of KAIDA floor system is also believed. After KAIDA seal curing treatment, the tire workshop has better ground effect and the overall surface layer is more compact. Usually, only water and KAIDA special cleaning agent can be used for cleaning! The moment to witness the miracle is coming. Let's take a look at the final effect. The tire workshop has different places on the ground. It has a few more lusters. It has both value and practical value, and it can also show reflections. It is comparable to computer effects. Figure! The effect of the tire workshop floor was appreciated by the leaders at all levels. When the foreign guests visited the workshop, they praised the ground of the tire workshop handled by our KAIDA floor system!